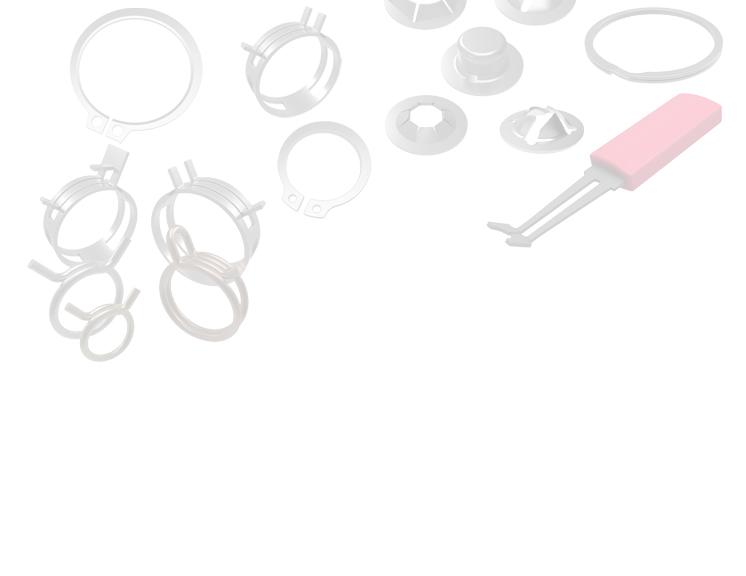

Plier type tools are available to ease installation on some series of rings.

Internal constant section retaining ring removal.

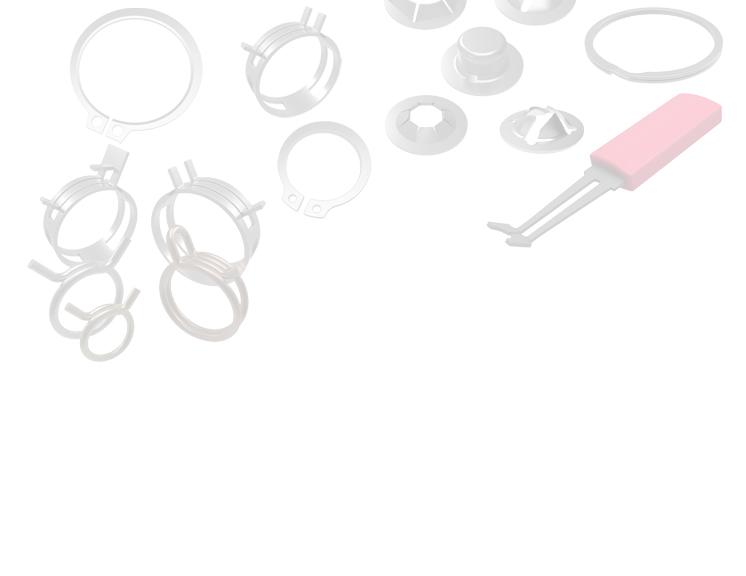

These internal rings come in a variety of configurations.

A retaining ring is a fastener that holds components or assemblies onto a shaft or in a housing bore when installed typically in a groove for one time use only.

Circlips are a type of retaining ring.

Constant section retaining rings are manufactured by coiling heavy section wire.

Spiral retaining rings come in single turn or multi turn varieties.

Circular push on retaining rings may be installed in applications where there is no.

Install and remove rings inside a bore or around a shaft.

Our eaton retaining ring selection includes internal external rings with a variety of gap styles.

The eaton snap ring also known as a constant section ring or eaton retaining ring is known for having a wide wall with proportioned thickness.

Internal retaining rings act as a removable shoulder within a bore housing.

This means that the material used to make the ring is the same width at any point along the circumference of the ring.

A constant section retaining ring snap ring is a retaining ring often specified for heavy duty or impact loading applications.

The constant cross section gives spiral retaining rings a lug free design making them suitable where available radial space is limited.

Standard duty fixed tip retaining ring pliers feature stop screws for positive location and return springs for ease of operation.

Heavy duty fixed tip retaining ring pliers.

Installed along the centerpoint of an axis horizontally constant section retaining rings feature a uniform constant section.

Sliding arm fixed tip retaining ring tools.

Sae products standard duty fixed tip retaining ring pliers for inch and metric internal and external retaining rings are available with straight 45 or 90 tips.

This process yields a retaining ring that supports high thrust loads.

Once installed the exposed portion acts as a shoulder which retains the specific component or assembly.

For installation in housings and shafts.

Constant section retaining rings.

They are typically rectangular wire created with carbon spring steel or stainless steel.

Multiple turn rings have higher thrust load capacity and feature a 360 retaining surface.

Many material and finish choices are available and custom designs typically do not require any custom tooling so.

Spring and stop eliminates overspreading of external rings and speeds the assembly removal of.

For applications that require an internal retaining ring smalley offers spirolox or internal spiral retaining rings hoopster rings constant section rings and wave rings.