Remove any siding or exterior finish that isn t compatible with vinyl siding and make sure the walls are sheathed with a substrate to receive the siding.

Installing vinyl siding with staples.

A staples wider head allows the siding to flex more.

Installing vinyl siding with nails vs.

Nails versus staples is an age old question in the vernacular of construction work.

Do not face nail or staple through siding.

Reverse the blade in the saw for extra smooth cutting through the vinyl and to.

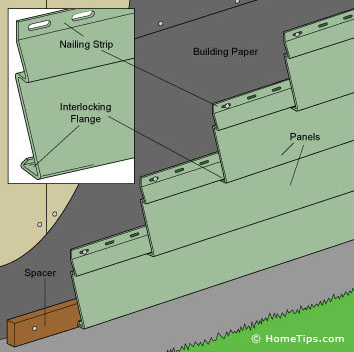

All fasteners must be able to penetrate a minimum of 1 1 4 32mm into nailable material such as wood sheathing and framing fig.

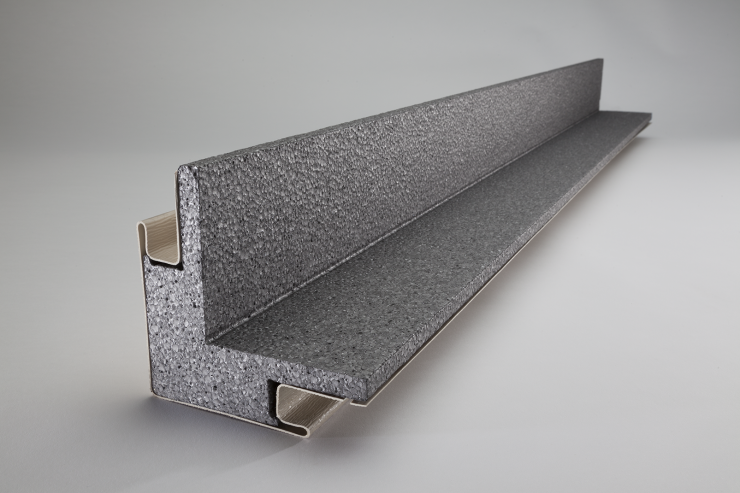

When applying vinyl siding staples must penetrate the backing wood by inch yet leave a gap of about 1 32 inch between fastener and siding.

Vinyl siding expands and contracts with outside temperature changes.

Learn more on proper nailing for vinyl siding installation how to install vinyl siding.

1 2 inch 1 3 cm plywood or osb are common substrates and these are generally covered with roofing felt or another moisture barrier prior to siding the walls.

Vinyl siding stapler offers good holding capability.

Take appropriate actions to ensure a smooth and continuous surface.

Use aluminum galvanized steel or other corrosion resistant nails staples or screws when installing vinyl siding.

Aluminum trim pieces require aluminum or stainless steel fasteners.

In re siding furring or removal of uneven original siding may be necessary.

Face nailing can result in ripples in the siding.

Depending on who you may talk to there will be differing.

Aviation and tin snip start cutting at the top interlock and continue toward the bottom of the panel.